This design can save space requiring less land area and shorter trenching when considering installing a horizontal slinky loop. DESIGN OF CLOSED-LOOP GEOTHERMAL HEAT EXCHANGERS IN THE US _____-----1 Chapter 24 DESIGN OF CLOSED-LOOP GEOTHERMAL HEAT EXCHANGERS IN THE US.

A Few Questions About A Horizontal Slinky Design Geoexchange Forum

There are different types of geothermal loops a open loop or a closed loop.

. Geo design software is engineered to take in account all these variables. They have the benefit of low installation costs in addition to the benefits of a closed loop circuit. House for each Geothermal System Type Open Loop Pumpinjection a 21 gpm well Vertical Closed Loop 3 wells 400 ft Horizontal Closed Loop Slinky 200 ft to 300 ft Standing Column Well 1 well 400 ft with bleed.

Because of the advantages of we use parallel circuits in ground loops almost exclusively in our industry. Slinky coil loops are one of the most common in geothermal ground loop design. Based on methods developed by the OSU Design Manual for the general method ASHRAE Design Manual for fundamental calculations CavanaughAlabama for lakepond calculations and NRECAOSUEPRI for Slinky calculations.

A water geothermal horizontal loop system utilizes a network of sealed and pressurized plastic pipes that are buried into the ground horizontally just below the earths surface. Minnesota geothermal heat pump systems are typically designed for the more rigorous demands of cold climate northern heatingwith additional high-efficiency summer cooling. Right-Loop provides quick easy and accurate geothermal loop designs that comply with all industry standards.

The geothermal ground loop design is a key part of the geothermal cooling and heating system and is designed by our in-house Geomaster Engineers. When loops are tied in series with one another they will all see the full. And to provide a geothermal design that could be applied to all six model homes offered in the development.

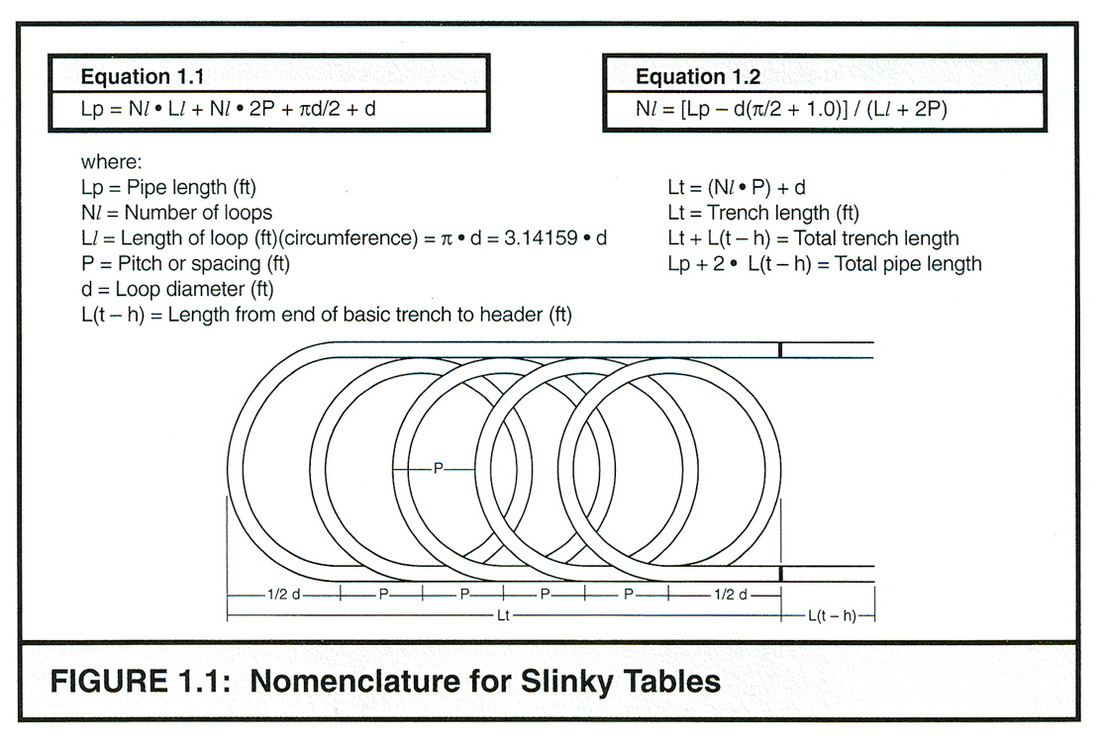

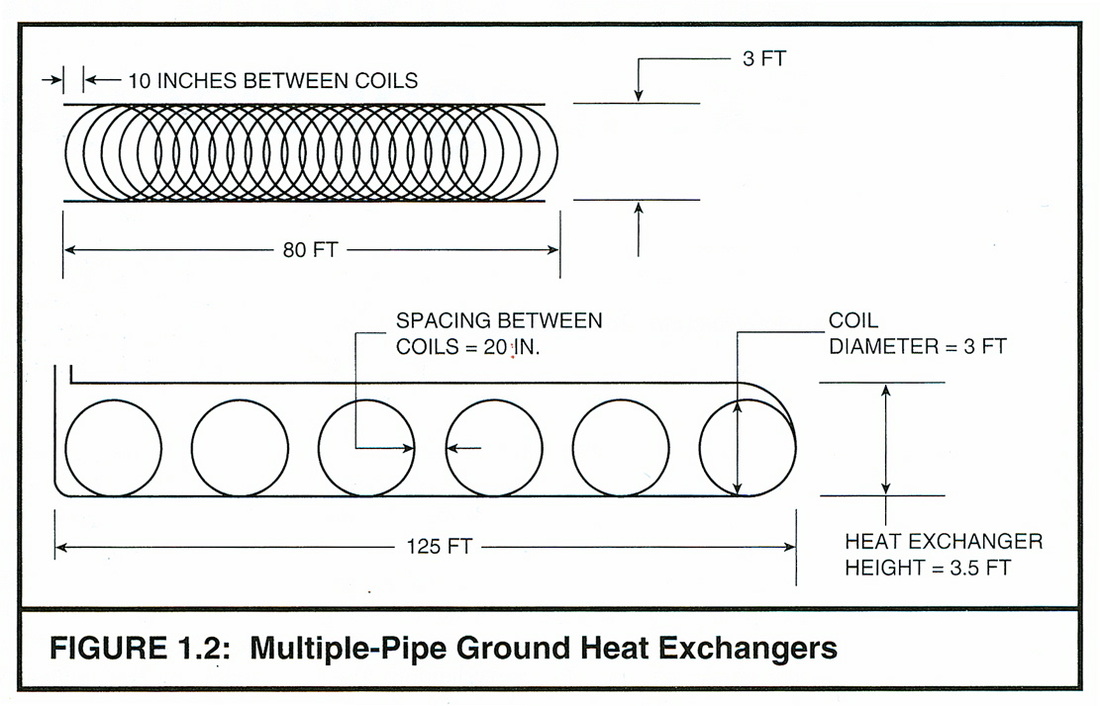

The overlapping coils made of polyethylene pipe are used to increase the heat exchange per metre of trench length but require more coils per kW of capacity. SLINKY 1000 feet 80 feet Extended SLINKY 500 feet 125 feet Four Pipe 500 feet 125 feet Note. These free calculators provide comprehensive design tools concentrating on the ground loop and pump selection portions of the system.

Edited by John W. Since they are buried in saturated soil we only needed 85-lineal feet of trench per slinky loop times 4 trenches. The geothermal earth loop or ground heat exchanger GHEX is the heart and soul of a geothermal heat pump GHP system.

When designing geothermal ground loops this is an issue that a lot of people get hung up on. A slinky loop of fluid-filled pipe performs the same function as any other horizontally-deployed ground loop pipe in a ground source heat pump system. Geothermal Loop Design.

We do not install slinky loop systems unless in water but we dig down 6-8 feet using one 500 to 600 feet of loop in a straight configuration. If you were to apply the laws of thermodynamics to ground loop design it would be clear that there is a limited amount of energy available from a given area of earth and a limited amount of energy. The trade off is that more feet of pipe needs to be buried.

One end of the loop is picked up and dropped in from the ground surface while a second individual further down the trench holds the loop over the trench. Series vs Parallel Flow Path Analysis. Geothermal slinky loop systems can be used in a ground loop pond loop or lake loop design and uses the earth as a heat source and heat sink.

Backfilling the first trench. 1000 of pipe in each loop. The Slinky loop design is another horizontal closed loop design.

Each trench 35 wide 6 deep 90 long. Yes a single loop spaced trench is more effective but excavation costs are higher. These slinky earth loops service a 3-ton geothermal heat pump.

Pe size is W4 inch. The other design uses horizontal racetrack loops 2400 of 125 pipe in one trench 4 wide 6 deep 300 long. The Closed-LoopGeothermal Heat Pump Systems Design and Installation Standards manual is intended as a source of minimum standards and guidelines for the design and installation of Closed-LoopGeothermal Heat Pump Systems.

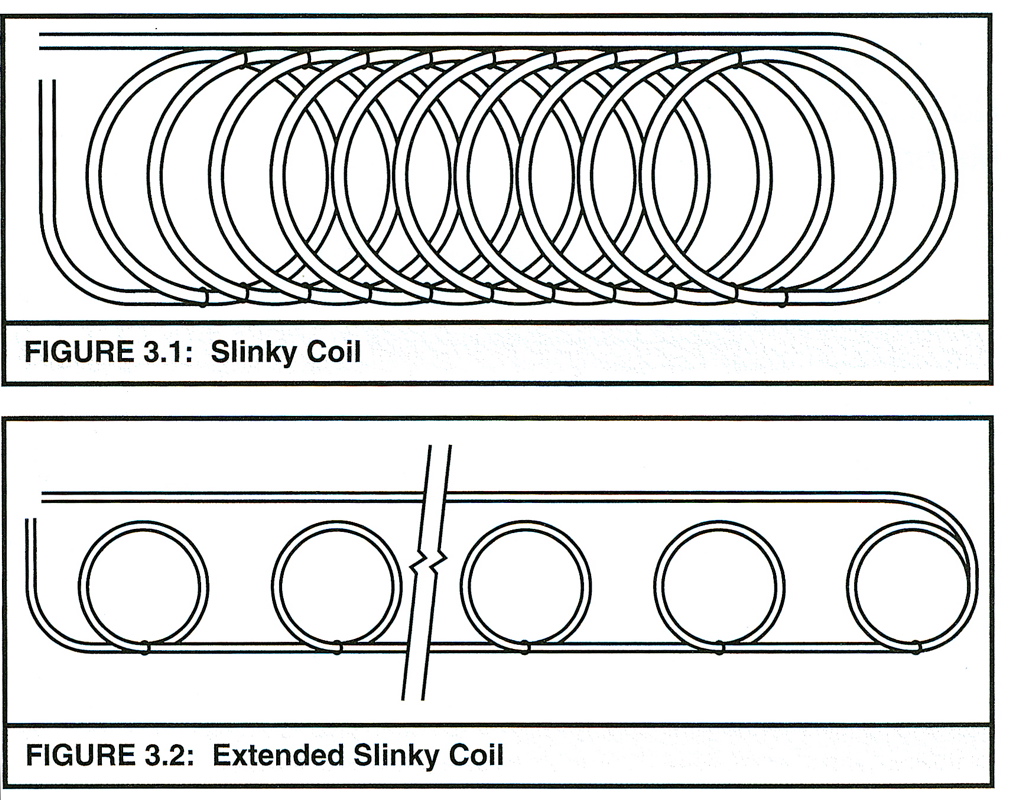

Figure 1 illustrates the pipe configurations of the two coils SLJNKY and Extended SLINKY that are under development and demonstration at this time. From time to time its the simplest styles that look the most effective as Eunkyung is a large admirer of the complete-color nail. A series of pipes commonly called a loop carry a fluid used to connect the geothermal systems heat pump to the earth.

Coil pitch distance htween mils for both coil types is shown on the drawing. But the slinky is different than straight pipe runs in that for the same amount of ditch length one can alter the spacing between pipes more uniformly than with multiple pipe loops at the same depth and with better thermal. Recently added a suite of Geothermal System Design Calculators to its website.

One design uses slinky loops 5000 of 34 pipe in 5 trenches. The two people can alternate moving down the trench while dropping the. Example of Slinky Loop in a Geothermal System.

It is more cost effective in my opinion to excavate wider trenches and lay multi-loops or slinkies. Read more to hear why. The plastic heat exchanger pipes are typically laid flat in a circular pattern at the bottom of a trench.

If there had been enough room for 115-foot trenches we could have gotten away with installing 3 slinky loops. You need a flow center to pump the water and antifreeze mix throught he loop. We have developed a non in the trench design and we use only one coil per trench.

The thinking that slinky loops will let you get the same or more geo capacity from a smaller loop footprint is dead wrong. Better communication between the loop contractor or driller and the heating and cooling contractor could help improve the loop field design noted Urlaub. Lay four pipes in the trench backfill 2 and pipes return at 4 deep.

The HVAC contractor sells and sizes the job and then usually tells the ground-loop subcontractor something like I need a 5-ton slinky loop installed at this address. Has six Geothermal System Design Calculators on its website and will be adding more. Geothermal slinky loop design.

It is a necessary tool for product developers and. The installation process begins by laying the slinky loop on the ground surface the entire length of the trench. Geo-Flo Products Corp.

Lund Geo-Heat Center E-mail. Also lake loops typically have more mild operating temperatures. Lake loops use coils in most cases the slinky loop design made of polyethylene piping or modern heat exchanger coils submerged into a lake.

Lundjoitedu INTRODUCTION Geothermal heat pumps aka ground-source heat pumps GHP or GSHP are used in two basic modes. This system uses slinky coils rather than straight pipe which are stacked. To reduce installation costs Ponikau ruled out a vertical loop and a traditional horizontal loop opting instead for a stacked slinky loop field.

Slinky Loops And Their Construction

Slinky Loops And Their Construction

Is This Ground Source Heat Pump Plan Workable Greenbuildingadvisor

Naeem S Slinky Earth Loop Installation

Geothermal Heat Pumps At Home Slinky Loops Design Horizontal Geothermal Heat Pump Istallations

0 comments

Post a Comment